CONTAINMENT FILTRATION

Improved protection and improved airflow cylindrical HEPA filtration for use in containment systems

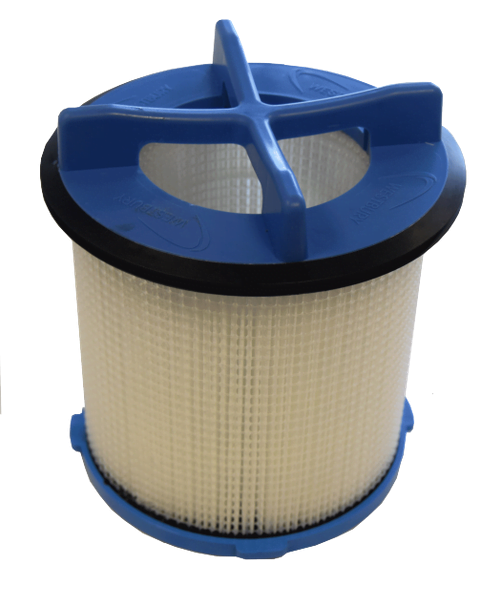

Our a glovebox push-through filter that doesn’t snag gloves, that is manufactured from modern materials and is easily disposed of when exhausted.

The new Push2 H14 Glovebox Push-through Hepa Filter combines all of the above attributes and will also last longer than the competition due to the extended filter surface area in the filter cartridge.

The continuous safety edge of the handle moulding, along with its modern ergonomic design, means that the filter can be easily and simply manoeuvred by the thickest isolator gloves – no more juggling with metal components that are difficult to grip and may tear the gloves.

The outer components of the filter are manufactured solely from modern moulded polymers and the entire filter contains no metal parts or components, so disposal is simple.

To demonstrate the superior performance of the Push2 Filter, Independently tested the filter to breach conditions ie: where the isolator integrity has been breached – typically a damaged glove. Throughout these tests, the filter retained its integrity and continued to deliver the required level of operator protection.

Every Push2 Filter is individually tested and provided with its own unique reference and test certificate. This information is also printed on the filter itself and on the protective carton in which the filter arrives.

PUSH2 150 Glove Box Push Through HEPA Filter

Applications

Designed to ensure the safe operation of chemical, pharmaceutical, nuclear & biological isolators, Push2 Cylindrical glove box filter has been designed using the very latest materials to provide lower resistance, longer life and stability even at isolator breach pressures.

Construction

The Push2 150 contains no metal parts and is therefore totally incinerable for ease of disposal. This feature, combined with the continuous safety edges of the moulding also means the product is safe and simple to use. The modern ergonomic design makes handling simple, even when being manipulated with the thickest isolator gloves. Integrated moulded continuous gasket ensures a perfect air seal every time. The product’s increased media surface area ensures the lowest possible pressure whilst

operating at full capacity. This in turn results in lower energy demand in operation. The standard operational flow rate of 40m3/hr (23.5 CFM) runs at only 110Pa (0.44”WG) and has been tested to 120m3/hr (70.6CFM) – simulating a typical isolator glove breach. Every Push2 filter is individually tested and the product supplied with its own individual test certificate, serial number and production date for full traceability.

Reviews

There are no reviews yet.